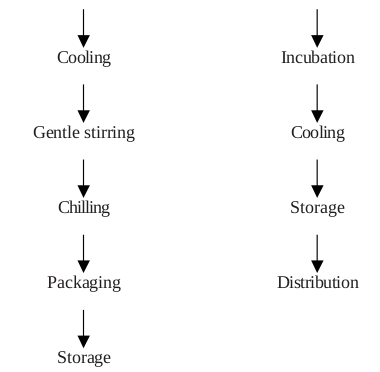

It is a cream product, which is prepared by ripening or souring of sweet cream to a titratable acidity of 0.60%, L.A with desirable lactic acid bacteria. It has slightly acidic flavour and smooth texture. Sour cream is usually used in the preparation of different foods and sometimes in drinks and beverages. The following steps are involved in the preparation of sour cream Fig

|

| Flow diagram for preparation of Sour cream |

Sour cream is prepared from fresh and sweet cream standardized to contain 18-20 % fat. The standardized cream is pasteurized by LTLT or HTST Method and cooled to 60-65°C. At this temperature it is homogenized employing two-stage homogenization process. Low temperature homogenization is preferred to promote formation of fat clusters, which during ripening flocculate and also increase the viscosity of the product and improve the texture. Homogenized cream is then inoculated with 2-4% fresh and active starter culture containing lactic acid and flavour producing microorganisms, namely, Streptococcus lactis, Streptococcus cremoris and diacetyl lactis. The inoculated cream is then incubated at a temperature of 22°C and allowed to develop titratable acidity and desired body and texture.Usually, it takes 10-12 hrs to attain the desired acidity. Sometimes some thickening agent or rennet is also added to sweet cream to increase the firmness of the sour cream. When the cream has attained the desired acidity (0.60% LA or pH 4.5) it is cooled with gentle stirring and chilled to 2-4°C followed by packaging.Alternatively, the cream after homogenization and inoculation is filled in the containers and the packages are incubated at 22-25°C. The acidity develops. Then the packages are transferred to cold rooms where cooling of the product is achieved.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.